Construction is usually back-breaking work that could result in long-term injuries. That’s why discerning workers and construction companies invest in high-quality tools to ensure safety in the workplace. One of these tools is the rebar bender, which will make it easier to bend solid steel rods to ensure that they meet the proper shape for building a solid wire frame. Manual bending can cause repetitive strain on the joints and muscles of your arm, resulting in chronic injuries down the line. You do not have to worry about that when you bend steel bars with a portable bender.

Using a rebar bender considerably reduces the time and the effort it takes to bend steel reinforcing bars into desired shapes. The portable tool is lightweight and easy to carry anywhere you need to work, thus, increasing productivity and reducing downtime. It ensures accurate bending at a high speed, usually accomplishing the task in at least five seconds, while ensuring that the rod is bent at an accurate angle. Rebar bending machines are capable of bending in a range of arcs, usually from zero to 180 degrees, so they should be able to meet any unique building specification. This is important when ensuring identical and accurate angles to firmly hold concrete.

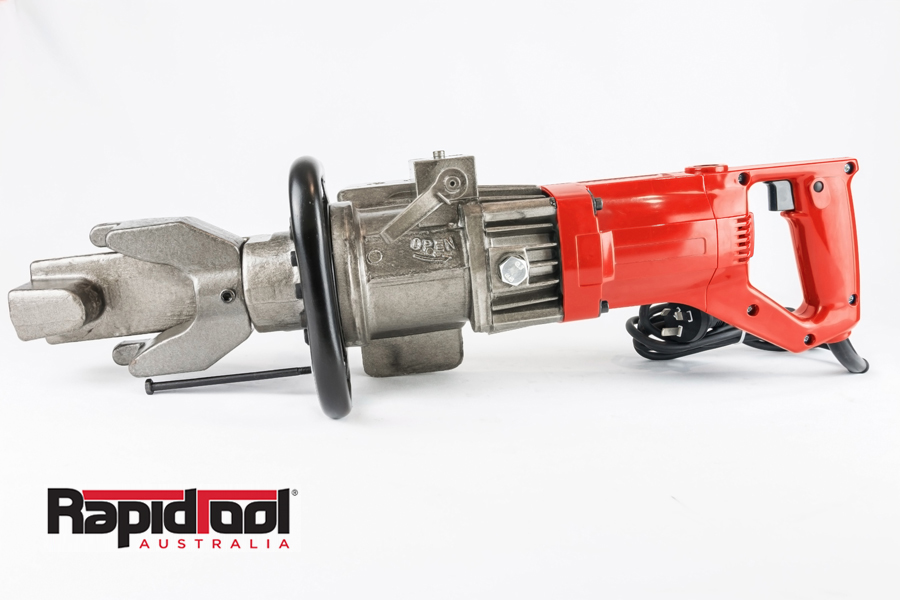

The rebar bender ensures high-quality and consistent results every time, unlike when you rely on manual labour. Simply set the tool to bend at a required angle, and it will do its job. Operating the bender is simple too, as you usually just need to pull a trigger or press a button. Another disadvantage to manual bending is the resulting superficial damage to the steel rod, which could affect the structural strength of the reinforced concrete. Bending machines have mechanical and electrical components that ensure a structured means of achieving a precise bend without excessive manipulation and the risk of damage to the material.